Compact size, light weight, flexible movement - an ultra portable laser welding machine launched by FANUCI. Available in the following power variants: 1000W, 1500W, 2000W. Maximum welding versatility and easy, intuitive use.

Fiber laser welding technology for metal processing is rapidly gaining popularity in the manufacturing sector, increasingly replacing traditional, outdated welding methods. This advanced technology offers unmatched precision, flexibility, and high-speed performance, making it suitable for even the most demanding industries. Fiber laser welding is extensively applied across various sectors, including aerospace, automotive, defense and military, medical devices, electronics, petrochemical refining, communications, energy, automation, and outsourcing.

Fiber laser welding by FANUCI represents a significant advancement in welding technology, offering numerous benefits that enhance productivity, quality, and cost-efficiency across various industrial applications.

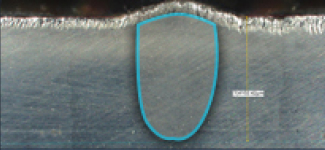

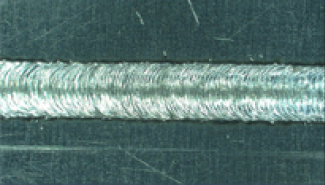

Stainless steel (4.5 mm)

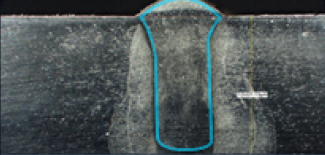

Carbon steel (4.5 mm)

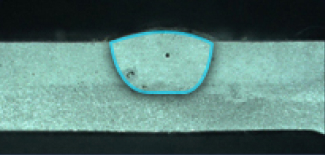

Aluminium steel (4.0 mm)

Stainless steel (4.5 mm)

Carbon steel (4.5 mm)

Aluminium steel (4.0 mm)

Stainless steel

Carbon steel

Aluminium steel

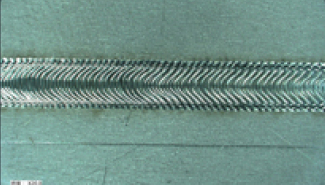

FANUCI 5th generation fiber laser welding machines represent the top of innovation and advanced technology in the welding industry. This cutting-edge equipment ensures unmatched stability, top-tier quality, and exceptional precision throughout the welding process. It is designed to seamlessly replace traditional welding methods, particularly for materials such as stainless steel, aluminium, carbon steel, titanium, copper, brass, and precious metals like gold and silver, as well as a wide range of other high-reflective materials.

Advanced Technology: FANUCI 5.0 PRO Portable embodies the latest advancements in fiber laser welding, offering superior performance and reliability.

Exceptional Precision: The technology ensures highly precise welds, enhancing product quality and reducing material wastage.

Versatility in Material Handling: Capable of welding a diverse array of materials, including high-reflective metals, making it ideal for various industrial applications.

Increased Production Volumes: The efficiency of the fiber laser welding process allows for higher production rates, significantly boosting productivity.

Cost Efficiency: By minimizing production costs through reduced material waste and lower energy consumption, FANUCI 5.0 PRO Portable provides an economically advantageous solution.

Warranty and Certifications: Backed by a comprehensive 2-5 year warranty, the machine is FDA, SGS, CE, and WPQR TUV Rheinland certified, ensuring compliance with the highest standards of quality and safety.

Absolute Superiority:

With its advanced features and superior performance, FANUCI 5.0 PRO Portable stands out as the leading choice for fiber laser welding.

Future-Ready

Designed with future advancements in mind, this equipment prepares manufacturers for the evolving demands of the industry.

Innovation Meets Excellence

Experience the cutting edge of welding technology with FANUCI 5.0 PRO Portable, where innovation seamlessly integrates with excellence to deliver unparalleled results.

Experience the future

Experience the future of fiber welding with FANUCI 5.0 PRO Portable, where revolutionary innovation and unparalleled excellence redefine the standards of welding technology.

FANUCI 5.0 PRO Portable fiber laser welding machine is equipped with state-of-the-art components that ensure superior performance and reliability. Each major part is developed and patented by FANUCI, ensuring proprietary innovation and technological advancement.

Configuration Options: Final specifications and features of FANUCI 5.0 PRO Portable depend on the chosen welder configuration, allowing customization to meet specific needs and applications. By integrating advanced, patented technologies and sourcing components from top-tier suppliers, FANUCI ensures that 5.0 PRO Portable fiber laser welding machine sets a new standard in the industry for quality, performance, and innovation.

| Component | Manufacturer | Options |

| Laser source | FANUCI PowerON | Fiber (1000W, 1500W, 2000W) |

| Laser head | RAPTOR 5.0 PRO | Wobble (single) |

| Control system | LaserWELD 5.0 PRO | 4in1 |

| Wire feeder | EasyWIRE 5.0 PRO | Automatic (single/double) |

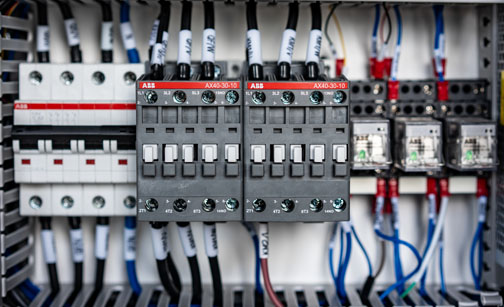

| Electrics | ABB Weidmuller | Integrated |

| Cooling system | ChillX 5.0 PRO | Integrated (air unit) |

| Fume filter | CleanAIR 5.0 PRO | External (automatic) |

| Safety | Workstation / DefenderVV | External (environment/operator) |

FANUCI PowerON Laser Source is engineered to deliver consistent and powerful output, ensuring optimal welding results. It is designed with advanced technology to provide high efficiency, precision, and reliability.

Key Features:

FANUCI PowerON Laser Source combines innovative technology with practical features to deliver superior welding performance, making it a reliable and cost-effective solution for a wide range of industrial applications.

RAPTOR 5.0 PRO Laser Head by FANUCI is designed to offer enhanced accuracy and efficiency with its patented single (4in1) oscillating beam movement. It combines advanced technology with user-friendly features to ensure optimal performance in welding applications.

Key Features:

RAPTOR 5.0 PRO Laser Head integrates advanced features to provide exceptional accuracy, efficiency, and versatility in welding applications. Its innovative design and user-friendly operation make it an ideal choice for achieving superior welding results.

LaserWELD 5.0 PRO Operating System, available in 4in1 configuration, offers versatile and robust control options for various welding applications. This advanced system ensures superior performance through intuitive and easy-to-use features, perfectly matched with the appropriate laser head.

Key Features:

Benefits:

LaserWELD 5.0 PRO Operating System, combined with RAPTOR 5.0 PRO Laser Head, delivers a powerful and efficient welding solution. Together, they provide unmatched precision, versatility, and ease of use, making them ideal for modern welding applications.

EasyWIRE 5.0 PRO Automatic Wire Feeder by FANUCI supports both single and double wire feeding, offering maximum flexibility for a variety of welding applications. Designed to work seamlessly with FANUCI laser heads and control systems, this wire feeder ensures optimal performance and adaptability to meet specific production requirements.

Key Features:

Benefits:

EasyWIRE 5.0 PRO Automatic Wire Feeder enhances the capabilities of FANUCI welding systems by offering flexible, efficient, and fully integrated wire feeding solutions. This makes it an essential component for achieving high-quality welding results in a variety of industrial applications.

FANUCI laser welders are equipped with the most reliable ABB electrical installation, ensuring a constant and safe power supply. This setup is crucial for maintaining uninterrupted operation and protecting the equipment and production process from electrical issues.

Key Features:

Benefits:

The integration of ABB electrical installation and security solutions in FANUCI laser welders provides a robust foundation for reliable and safe operation. This ensures that the welders can perform at their best, supporting high-quality production processes and business continuity.

FANUCI ChillX 5.0 PRO air cooling system is designed to provide highly efficient cooling for both the laser source and the welding head simultaneously. This advanced cooling solution ensures optimal operating temperatures, enhancing the performance and longevity of the equipment.

Key Advantages:

Benefits:

ChillX 5.0 PRO air cooling unit by FANUCI is a vital component for maintaining the efficiency and durability of laser welding equipment. Its advanced cooling capabilities, combined with user-friendly features, make it an essential addition to any modern welding operation, ensuring both high performance and reliability.

CleanAIR 5.0 PRO fume filtering unit by FANUCI is designed to automatically remove vapours and dust from the working environment, promoting a healthier and safer workspace. This advanced system not only benefits the environment but also enhances the longevity of consumable parts and offers additional operational advantages.

Key Advantages:

Benefits:

CleanAIR 5.0 PRO fume filtering unit by FANUCI is an essential component for maintaining a safe, healthy, and efficient working environment. Its advanced features ensure that harmful particles are effectively removed, protecting both the operator and the equipment while supporting eco-friendly practices.

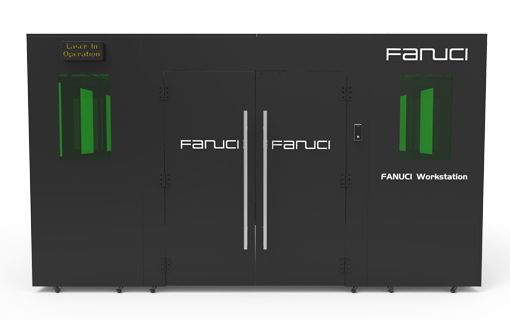

Safety is paramount in any working environment, especially in high-risk areas such as welding workstations. FANUCI provides advanced safety equipment designed to protect operators and bystanders, preventing dangerous situations and ensuring a secure workplace.

Key Advantages:

Benefits:

FANUCI Workstation safety equipment is designed to provide comprehensive protection for both operators and bystanders, preventing dangerous situations and ensuring a safe working environment. With customizable solutions and advanced safety features, FANUCI sets the standard for safety in welding operations.

Safety is a top priority in any workplace, especially in environments with potential hazards like welding operations. FANUCI DefenderVV protective mask is designed to ensure that operators are fully protected at all times, helping to prevent hazardous situations. DefenderVV mask is available in two options: BASIC and PRO, each offering superior protection and comfort.

Key Advantages:

Benefits:

Always Remember to Stay Protected!

By using DefenderVV protective mask, operators can work confidently and safely, knowing they are protected from the various hazards associated with welding and other industrial operations. Whether choosing the BASIC or PRO version, DefenderVV mask by FANUCI offers reliable protection and comfort, making it an essential piece of safety equipment in any workplace.

Technical parameters of each fiber laser welding machine depend on the chosen model configuration. Final specifications are predetermined in our commercial offers. For further information, please contact us.